Bandsaw Blade Setup & Cutting Guide

This guide covers the key setup and cutting practices to get the best performance and blade life from SharkTooth bi-metal bandsaw blades on horizontal saws.

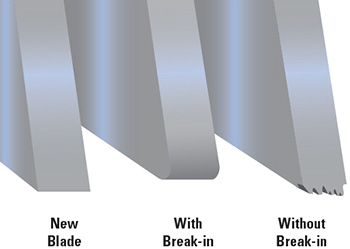

1) Break-In New Blades (Critical)

Correct break-in prevents tooth chipping and can significantly extend blade life.

Break-in steps (Bi-Metal Blades):

- Install the blade correctly (tooth direction, guides set, correct tension)

- Run full blade speed

- Reduce feed pressure to ~50%

- First cuts:

- Solid material: first few cuts at reduced feed

- Tube / structural: first 5–10 cuts at reduced feed

- Gradually increase feed back to normal over the next few cuts

Why it matters: New teeth are extremely sharp. Break-in gently rounds the tooth tips, preventing micro-chipping.

2) Choose the Correct Tooth Pitch (TPI)

Matching tooth pitch to the material is essential.

- 3-4 TPI and 2–3 TPI: large solids, heavy structural steel

- 5-8 TPI and 4–6 TPI: general fabrication

- 6-10 TPI and 10–14 TPI: thin wall tube and light sections

Rule of thumb: Always keep at least 3 teeth engaged in the cut.

3) Speed & Feed Control

Incorrect settings are one of the most common causes of blade failure.

- Too fast → overheating and rapid wear

- Too slow → poor finish and tooth damage

Set blade speed and feed rate to suit the material being cut. Use your saw manufacturer’s recommendations as a starting point.

4) Coolant Application

Coolant is critical for blade life and cut quality.

- Reduces heat

- Lubricates the cut

- Flushes chips away from the blade

Keep coolant clean, correctly mixed, and aimed directly into the cut zone.

5) Blade Tension & Tracking

Incorrect tension affects accuracy and durability.

- Too low → blade wanders, cuts out of square

- Too high → blade or machine damage

Always tension the blade to the saw manufacturer’s specification.

6) Keep the Saw Clean

Chip build-up reduces accuracy and increases wear.

- Clean guides and wheels regularly

- Remove swarf from the cutting area

A clean saw cuts straighter and extends blade life.

7) Common Problems & Likely Causes

| Problem | Likely Cause |

|---|---|

| Tooth stripping | Feed too heavy or wrong TPI |

| Blade wandering | Low tension or worn guides |

| Short blade life | Poor break-in, no coolant, incorrect speed/feed |

Fixing the cause early prevents repeat failures.

8) Replace Blades Before Failure

Replace the blade when you notice:

- Slower cutting

- Increased noise or vibration

- Poor cut finish

Running a blade until it snaps usually costs more in downtime and scrap.

Need Help Choosing the Right Blade?

We supply and support Cosen, IMET and Daito horizontal bandsaws and can recommend the correct SharkTooth blade and coolant for your machine and application.

Contact us for practical advice and proven cutting solutions.